Mobile Laminar Air Flow Unit with Trolley

Price 45000-100000 INR/ Piece

Mobile Laminar Air Flow Unit with Trolley Specification

- Feature

- Mobility with lockable castor wheels, vibration free operation, low noise

- Filter Type

- HEPA (High Efficiency Particulate Air), Pre-filter

- Floor

- Stainless steel or anti-microbial PVC mat

- Material

- Stainless Steel (SS 304) or Mild Steel with Powder Coating

- Filters

- Pre Filter (EU 6), HEPA Filter (EU 14)

- Application

- Hospitals, Laboratories, Pharmaceutical industry, Sterile area operations

- Power Consumption

- 0.5 kW to 1.5 kW (depending on model)

- Voltage

- 220V AC / 50 Hz

- Door

- Polycarbonate/Acrylic Hinged or Sliding Door

- Nozzle

- Air distribution nozzles for uniform flow

- Type

- Mobile Laminar Air Flow Unit

- Lighting

- Fluorescent Lamp / LED Light, UV lamp 1 x 30W

- Air Volume

- 700-1200 m/hr (model specific)

- Condition

- New

- Air Flow

- Horizontal/Vertical laminar airflow, 0.45 0.05 m/s

- Frame Material

- Stainless Steel (SS 304) / MS Powder Coated

- Thickness

- 1.2 mm / 18 SWG (Typical)

- Weight

- Approx. 65-120 kg (depending on size)

- Dimension (L*W*H)

- 1200 x 600 x 1800 mm (custom sizes available)

Mobile Laminar Air Flow Unit with Trolley Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 7 Pieces Per Week

- Delivery Time

- 3-4 Week

About Mobile Laminar Air Flow Unit with Trolley

We are reputed manufacturer, trader and supplier of the various items. Here our firm is providing top-quality Mobile Laminar Air Flow Unit with Trolley to our client that is made with qualitative required materials with the help of advanced technology. It is used for move the item from sterile territory to sterile region from non sterile region. This Mobile Laminar Air Flow Unit is utilized in the mechanical assembling for the insurance of the item in the different territory.

Reliable Clean Air Wherever You Need It

Mobile Laminar Air Flow Units bring sterile, filtered environments to any location within your facility. Heavy-duty castor wheels with locks give you effortless, secure mobility between rooms, whether you work in hospitals, laboratories, or pharmaceutical settings. The units horizontal or vertical airflow can be customized, creating highly controlled and contaminant-free workspaces for critical sterile operations.

Advanced Features for Operational Excellence

The unit incorporates a touch/push button control panel, magnehelic gauge for precise pressure monitoring, UV lamp with exposure timer, and transparent acrylic sides for visibility. Optional accessories, including gas and vacuum taps and a bag-in-bag-out filter system, provide added utility and safety. The stainless steel worktable (grade 304) is jointless, ensuring easy cleaning and durability for daily professional use.

Quality Construction Ensures Performance

Manufactured from premium stainless steel or powder-coated mild steel, the mobile unit is built for resilience and long-term use. The surface features a matt or satin finish for SS models and includes precise cabinetry with 1.2mm thickness. Dimensions are customizable, allowing you to select the size that best suits your sterile workspace requirements.

FAQs of Mobile Laminar Air Flow Unit with Trolley:

Q: How does the mobile laminar air flow unit enhance sterile operations in hospitals and laboratories?

A: The unit delivers a consistently filtered, particle-free airflow (0.45 0.05 m/s), achieved through high-efficiency HEPA and pre-filters. Mobility allows it to be positioned wherever sterility is essential, supporting critical tasks in hospitals, laboratories, pharmaceutical production, and other sterile areas.Q: What process should I follow to operate and monitor this laminar flow unit effectively?

A: Start by positioning the unit at your desired location and locking the castor wheels for stability. Use the touch/push button control panel to activate airflow and lighting. Monitor pressure drops via the magnehelic gauge. Use the integrated UV timer to track UV lamp exposure for disinfection. The units jointless stainless steel table facilitates easy work and cleaning.Q: When should the filters or UV lamp be maintained or replaced?

A: Filters, including the HEPA and pre-filter, should be inspected regularly and replaced when the magnehelic gauge indicates significant pressure drop. The UV lamp should be replaced if its timer reaches the manufacturers suggested operating limit, ensuring continued effective sterilization.Q: Where can this mobile laminar air flow unit be used?

A: It is suitable for a variety of controlled environments including hospitals, research laboratories, pharmaceutical production, and sterile processing areasany location requiring mobile, confined clean air workspace.Q: What are the main benefits of its mobility and lockable castor wheels?

A: Mobility allows effective distribution of sterile airflow wherever needed. The lockable heavy-duty castor wheels ensure stability during operation, preventing accidental movement and maintaining safety within busy workspaces.Q: How is electrical utility managed for equipment and instrumentation?

A: The unit is equipped with dedicated utility sockets, allowing convenient connection of electrical devices and lab instruments needed for your work process while maintaining a safe and organized workspace.Q: What optional accessories are available to customize the laminar air flow unit for specialized applications?

A: Optional accessories include gas and vacuum taps for laboratory work, a bag-in-bag-out filter system for safe filter replacement, and selections for door type (polycarbonate/acrylic, hinged or sliding). Special features and dimensions can be requested to match facility requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Shower Category

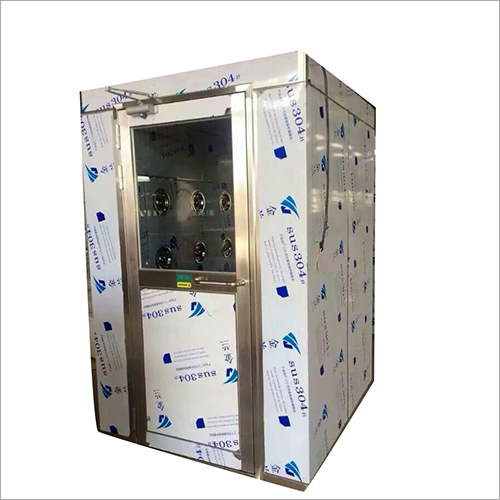

Stainless Steel Air Shower

Price 45000 INR / Piece

Minimum Order Quantity : 1 Piece

Application : Cleanroom, Laboratory, Pharmaceutical Industry

Feature : Touch Control Panel, Emergency Stop, Interlocking Door System

Material : Other, Stainless Steel (SS304)

Condition : Other, New

Air Shower

Minimum Order Quantity : 1 Piece

Application : Industrial

Feature : Good Quality

Material : Other, SS 304 /Aluminum Anodized.

Condition : New

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry